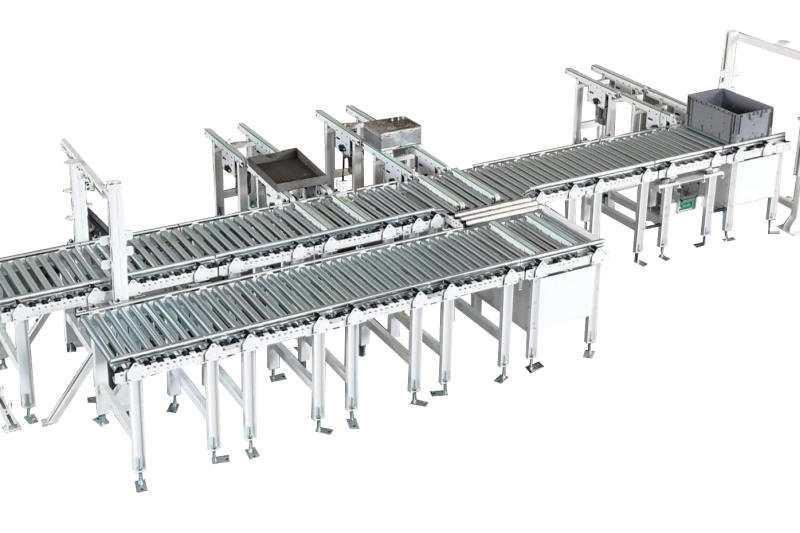

Crate transport and sorting system, with roller conveyors

equipped with motor rollers and belt conveyors.

2 or 3 WAY ORTHOGOGONAL TRANSFER

Composed of:

A) ELECTRIC LIFT STROKE 80 MM FOR ROLLER CONVEYOR

– Width 940 or 1140 mm

– Motovario motor from 0.75 to 1.1 kW

– Voltage 400V _Hz50

– Capacity: 1500 kg

B) MOTORIZED ROLLER CONVEYOR

– Length 1524.0 mm or 1676.4 or 1828.8 mm

– Useful width 940 or 1140 mm

– Speed 15 m/1’

– Roller pitch 152.4

– Galvanized rollers diameter 60 – 76 – 89

– Height from mm 620 to 700

– Motovario motor kW 0.37 – 0.55 – 0.75

Voltage 400V _Hz50

C) 2 or 3 TRACK CHAIN 3/4″S._ 3/4 “D.

– Center distance mm 1000

– Lengths from mm 1500 to 3500

– Speed 12 m/1’

– Height from mm 680

– Motovario motor kW 0.55 to kW 1.1

– Voltage 400V _Hz50

A crate transport and handling system is an advanced logistics automation solution designed to enable fast and precise sorting of boxes and containers.

The system includes various mechanical components such as electric lifters, motorised roller conveyors and chain conveyors, which work together to automate material flow.

Its main purpose is to optimise the sorting process by directing each unit to the correct destination according to operational requirements.

Adopting such a system offers numerous immediate benefits, including faster processing, fewer sorting errors and significant flexibility in adapting to the existing production layout.

The crate transport and handling system consists of an electric lifter with an 80 mm stroke, a motorised roller conveyor with zinc‑plated rollers and a 2‑ or 3‑track chain conveyor.

Designed for loads of up to 1500 kg, it can be customised in length, width and height.

It ensures speeds of up to 15 m/min and smooth integration into industrial processes.

Motovario motorisation and a 400 V – 50 Hz power supply guarantee reliability and compatibility with existing plants.

Choosing us as your partner means relying on a company that designs and manufactures its machinery internally, subjecting it to rigorous periodic testing.

We offer a complete turnkey service, from initial technical consultancy to long‑term support, with a constant commitment to improving the technologies selected by our customers.

We analyze your production needs and propose the most suitable automation solution.