Cold dehumidifier through moisture condensation on vane radiator. This system offers an optimal process, without the need to heat the honey. This has huge advantages:

• No loss of aroma or perfume

• No risk of sugar caramelization therefore, no color changes and honey does not turns into mou.

• It does not stress or pasteurized honey, it does not incorporate air

• HMF value does not rise as it happens in others models on the market.

• It improves the taste and it does not reduces the diastase value

• It is easy to load and lift, thanks to the underlying platform

Double wall bulkhead with water inside and an electric heater, in case you want to use it to melt crystallized honey. Low energy consumptions and overall dimensions. It is equipped with a transparent lid to check all the processing stages.

An electronic board and a temperature probe are installed to verify honey temperature and to set working temperature. It can be used to melt honey in jars before the selling.

Optional: creamy honey (deucream) and cold dehydration of pollen (deupol).

The AMA honey dehumidifiers offer a professional solution for treating honey without altering its natural properties.

The AMA 900 model uses a cold‑processing system with condensation on finned radiators, avoiding invasive heating and preserving aroma, colour and flavour.

This technology prevents HMF levels from increasing, does not reduce diastase activity and does not incorporate air, ensuring a high‑quality final product.

Its compact structure and integrated platform make loading and moving easier, making the AMA 900 ideal even for small laboratories.

Equipped with a double‑walled cradle with heating element, transparent lid and electronic temperature control, it can also be used to melt crystallised or jarred honey.

Optional features include the deucream function for creamy honey and deupol for cold pollen dehydration.

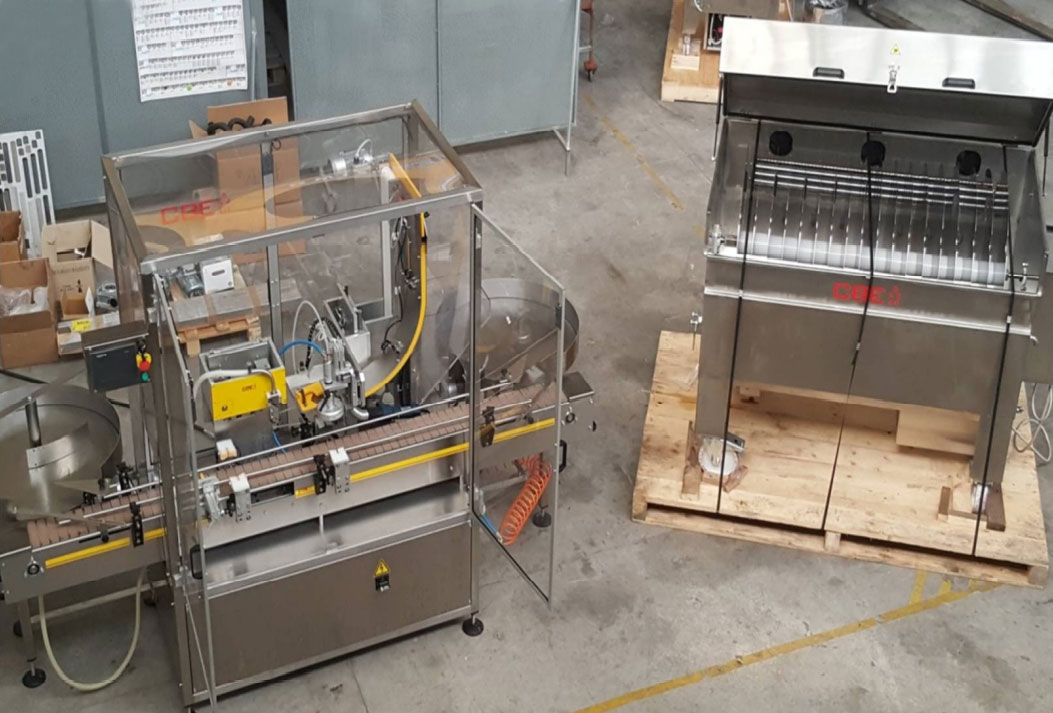

Why rely on CBE

Active on the market since 2005, CBE offers more than 15 years of specialised experience to professionals in the beekeeping, food and chemical‑pharmaceutical sectors.

The company designs and develops tailor‑made systems and highly customised solutions, with strong expertise extending to packaging and automation.

By using top‑quality raw materials, CBE guarantees high efficiency and industrial robustness while maintaining the artisanal attention to detail that sets its work apart.

Customers benefit from constant, precise technical support covering every stage — from project development to after‑sales assistance — ensuring long‑term reliability and maximum performance from every machine.

We analyze your production needs and propose the most suitable automation solution.