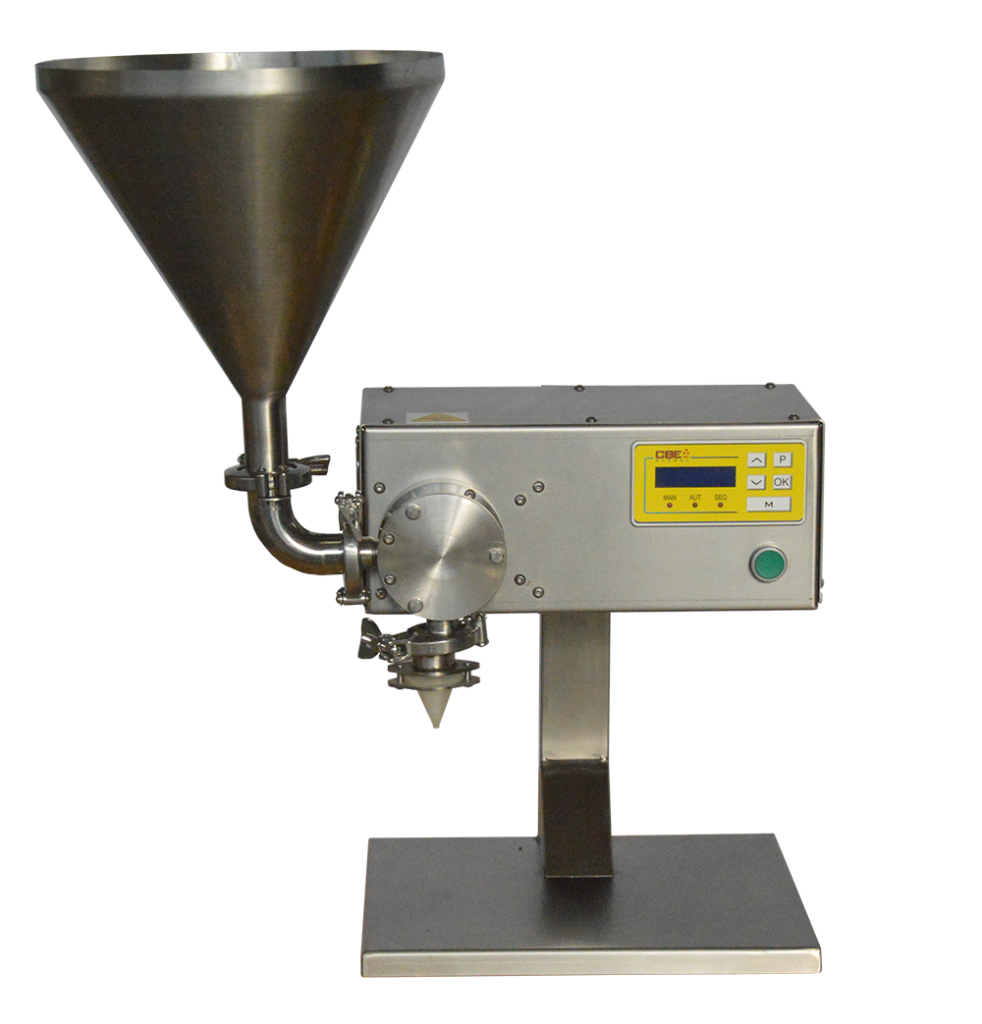

Tabletop electronic dosing machine for hot products, with pieces inside (up to 10mm) even when hot, or for processing crystallized honey and transforming it into creamy.

It is equipped with a vertical support, adjustable in height depending on the size of the jars to be filled. It is possible to adjust the dosing weight via display starting from 10g. Our table-top dosing machine was designed for dosing honey or liquid, dense or semi-dense products in particular.

The fundamental characteristics of this table-top dosing machine table are the calibration precision of the product and the output speed of the product, all features that can be selected thanks to the operator panel.

How to use:

manual: I can fill as much product as I want, with manual on off

Automatic: I select the recipe and it is repeated when the button/pedal is pressed

Sequential : repeats the recipe with a stop interval, no need to give the single command

Self-learning: I fill a jar as much as I want and save the recipe. No need to type the settings by hand

Positioning under the head (product output level, higher than the dosing head) or with the cone is recommended.

The components are made entirely of stainless steel or food-grade plastic and easily removable for thorough cleaning, even in the dishwasher.

Optional: 5.9 kg cone, in stainless steel

The Neo electronic tabletop doser is designed for the precise dosing of hot products, including those containing pieces up to 10 mm, such as crystallised honey and its transformation into creamy honey.

Thanks to its height‑adjustable vertical support, it easily adapts to the size of the jars being filled, ensuring flexibility and practicality during packaging operations.

The dosing weight can be set via the digital display starting from 10 grams, with the option to adjust parameters such as output speed and calibration accuracy directly from the operator panel.

This electronic bench‑top doser is particularly suitable for filling liquid, dense or semi‑dense products.

Several operating modes are available — manual, automatic, sequential and self‑learning — allowing the machine to adapt to any production requirement.

The recommended positioning is under head pressure or with a hopper, to facilitate product flow.

Made entirely of stainless steel and food‑grade plastic, the machine can be easily disassembled and washed, including in the dishwasher.

Among the available options is a 5.9 kg stainless‑steel hopper.

Why choose CBE’s electronic tabletop doser

CBE has over twenty years of experience in the design and manufacture of equipment for the food and industrial sectors.

Our role as a strategic partner is based on direct control of every production stage: each piece of equipment is the result of careful design analysis and is manufactured in‑house only after passing strict quality tests.

The company’s primary goal is the continuous improvement of its machinery, supported by a complete service offering that provides professionals with specialised consultancy and long‑term technical support even after purchase.

We analyze your production needs and propose the most suitable automation solution.